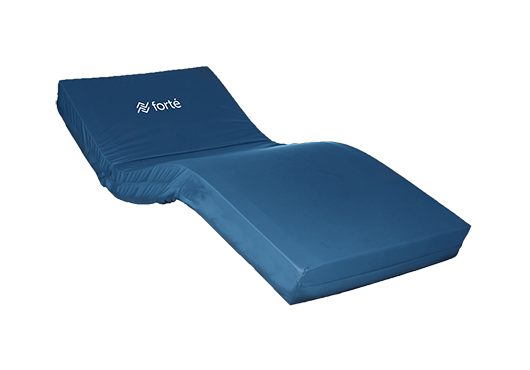

Airoform Memory

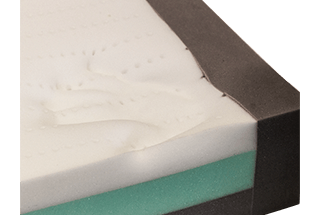

Airoform Memory Immersion Technology

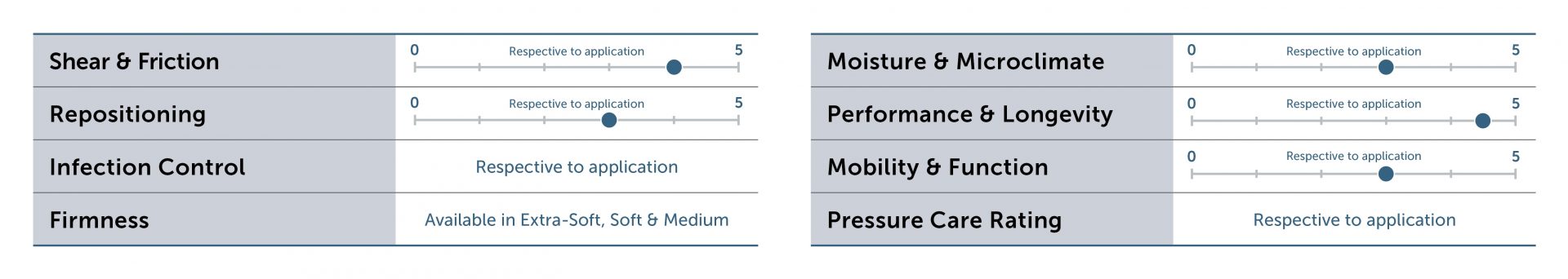

The Airoform Memory technology provides true Memory Foam Comfort, Enhanced Breathability and Lasting Performance.

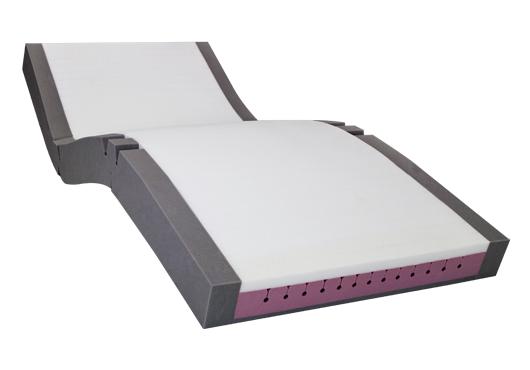

The viscoelastic cell structure is engineered for flotation and support ensuring its pressure care properties are retained over the duration of use. Can be used as a pressure care overlay, or as the or part of the interface layer on any mattress.

Features

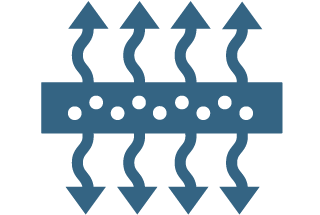

MICROCLIMATE

- Available with the ‘Breathe’ technology – perforations and open-cellular structure assists with dissipation of heat and circulation of air within the mattress. Provides greater circulation than conventional Memory Foams

COMFORT

- Available in Extra-Soft, Soft and Medium

SKIN INTEGRITY AND PRESSURE CARE

- Provides Excellent Pressure Redistribution and extremely low interface pressure

- Maximises the Contact Between the Patient and the Surface, Decreasing Interface Pressure

- Offers good heat stability and sustained immersion

CONTRAINDICATIONS

- Hot-Sleepers’ may be better suited to Airoform Gel and/or Airoform Response

- May not be suited for patients requiring high surface responsiveness to aid repositioning

TYPICAL APPLICATIONS FOR THE AIROFORM FOAMS

- Foam Overlays – available with or without covers. Read more about the Forté medical cover options

- Customisation to any Forté mattress to meet specific comfort and clinical requirements. Read more about Our range of mattresses, any mattress with an Airoform foam as standard can be swapped or added to with another Airoform layer/s.

About Airoform Memory

Immersion Technology

Airoform Foam

Excellent Immersion

Shear Mitigation

Gentle Care

WHAT IS VISCO-ELASTIC / MEMORY FOAM?

Visco-elastic foam is an elastic foam, also sometimes termed memory foam. It is a blend of polyurethane foam that was developed for aeroplane cushions by a NASA contract in the 1970s.

The difference between visco-elastic foam and other types of polyurethane foam is its slow response and low resistance. Its soft surface allows for contouring and its slow response lowers bounce.

One of the key benefits of visco-elastic foam is its contouring comfort.

Viscoelastic foam compresses due to pressure and body heat, and slowly sinks to cradle body contours. When you remove the heat and pressure the foam rises, remembering its former shape.

Originally, visco-elastic foam was developed for space research, later, due to its good pressure relief, the material was mainly used to make hospital beds for bedridden patients. Recently, the viscoelastic mattress has enjoyed wide popularity and is appreciated for its snug and cosy feeling during sleep.

Visco-elastic foam’s density makes it almost impossible to penetrate with dust, mites, or other undesirable substances. Instead, it settles on the surface which you can easily wipe down. Its inability to hold the irritating particles makes it hypoallergenic, and great for sensitive skin.

As the viscoelastic foam is so dense, it overheats easily. It is an excellent substance for winter mattresses, however, It can get very warm in summer though, which is one of its main disadvantages. Forté used a ‘Breathe’ technology to manage heat retention. Airoform Memory Breathe foam has holes throughout the foam that act as a ventilation system.

Another disadvantage is how there’s no real way you can escape the sinking sensation of the mattresses enveloping and cradling you by night. This sensation can restrict mobility and impact personal comfort.

VERSATILITY

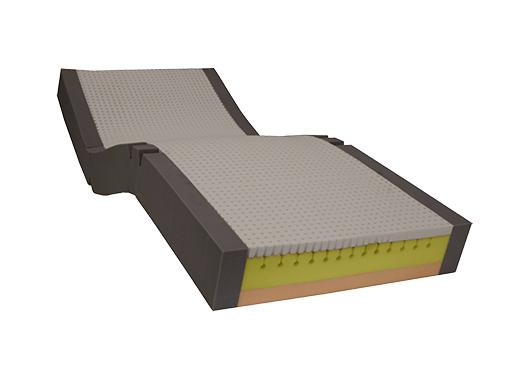

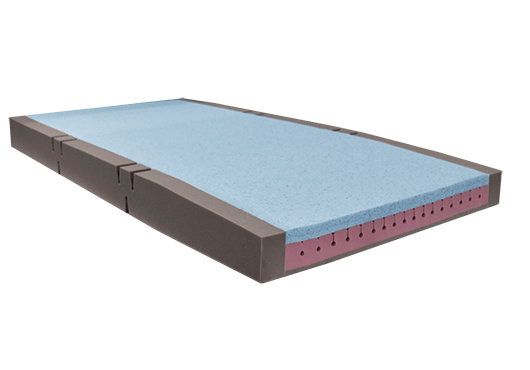

Airoform foams can be used in many applications, however, are predominantly used as an immersion layer on a mattress or as a separate foam overlay.

Any support surface manufactured by Forté can be customised in size and configuration to suit the specific needs of an individual – both from a clinical and comfort aspect. A common customisation is to swap the existing immersion interface layer with a different foam from the Airoform range.

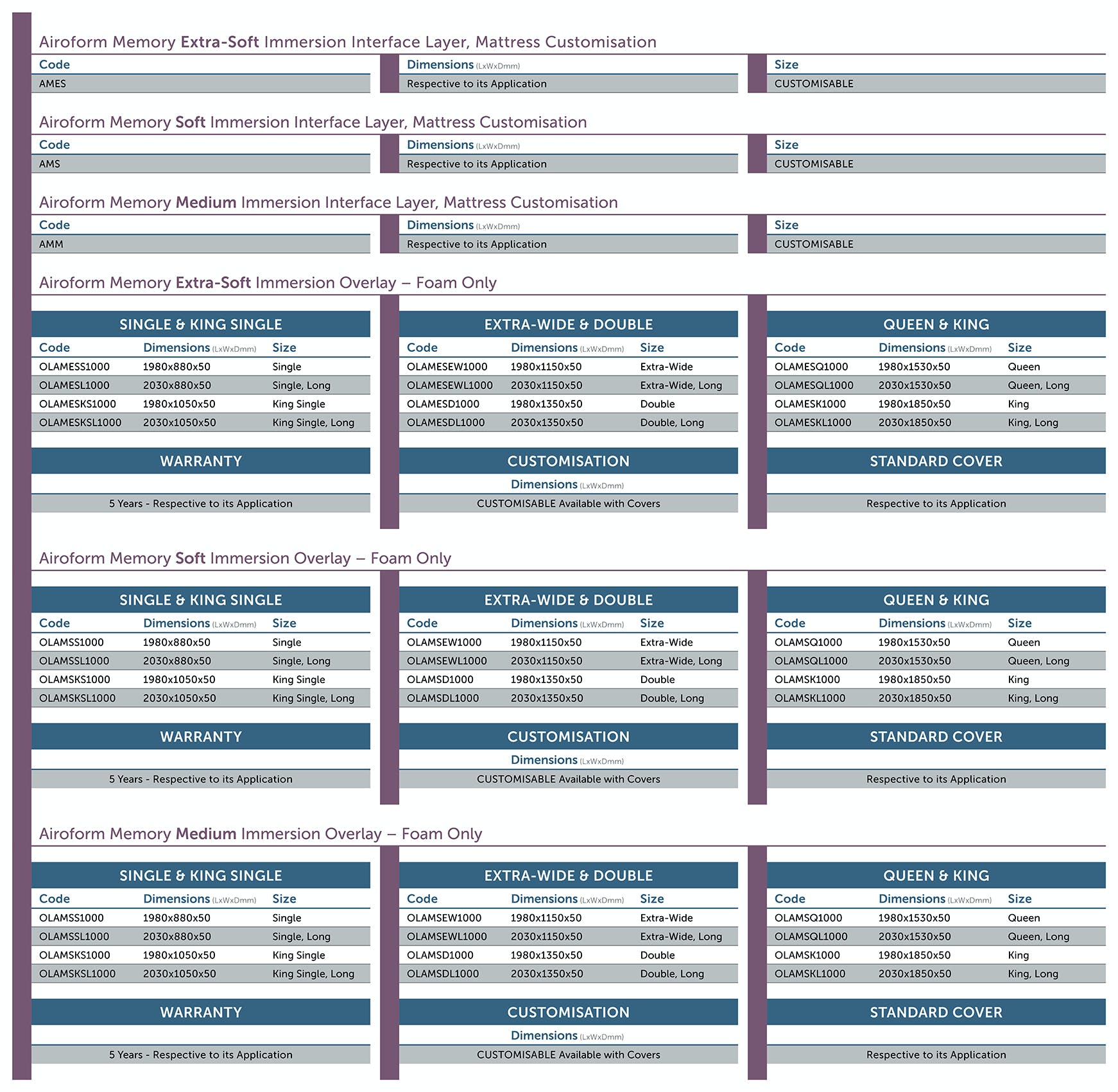

Airoform Memory is available in Extra-Soft, Soft and Medium firmness, and can be used to make up part of any mattress.

Airoform Memory is also available with a ‘Breathe’ ventilation system applied to provide extra breathability to the foam.

Trial kits are available to trial a mattress utilising all the different Airoform Immersion foams until you find the perfect configuration for you. Contact us if you are interested in finding out more!

AUSTRALIAN MADE

The Forté production facility in Armidale is specifically dedicated to Medical Mattress’ design, development, and production. This ensures unrivalled expertise and process control for superior quality, value, and performance. Forté utilizes leading global technology and research in the design and development of each medical device. Products manufactured by Forté in Australia are produced in compliance with local regulatory standards and exceed clinical standards recommendations such as European Pressure Ulcer Advisory Panel, National Pressure Injury Advisory Panel and Pan Pacific Pressure Injury Alliance – a quality you can trust!

Australian made by Forté Healthcare in Armidale NSW, the Airoform Memory technology is synonymous with quality, performance, longevity, and functionality and is trusted by leading Hospitals and healthcare professionals to deliver clinical results and positive outcomes.

Why is it important to purchase Australian made products?

By purchasing products from Forté you are investing into the future of pressure injury prevention in Australia, creating regional jobs and boosting our economy for the better of everyone. Australian Made for Australian Care.

MEDICAL FOAM TECHNOLGY

Airoform Memory foams are specifically formulated for use within high humidity applications, typical within Hospital applications where the mattress has low rest periods and is fitted with Moisture Vapour Permeable Covers. ‘Humidity’ treatment ensures that the structural integrity of the foams remains within conditions that would otherwise have a significant degrading effect on foam performance. It also ensures postural support is maintained for comfort and prevents excessive pressure forces because of foam collapse. It is crucial to pressure injury prevention that the foam maintains its support to prevent a ‘bottoming out’ effect and ensure immersion and envelopment.

Foams are also treated with Eversheild Anti-Microbial protection to prevent the growth of mould and bacteria. Maintaining healthy conditions within the foams reduces risk of infection control, cross patient contamination and mould.

Foams are individually sourced and selected as raw materials by Forté Healthcare from verified manufacturers within Australia, Europe and United States for guaranteed compliance with International standards. Forté provides complete supply chain transparency, benefiting the user by ensuring ultimate governance on quality and raw material safety especially necessary as Medical Mattresses are used in very close physical proximity to vulnerable users.

Manufacturing

Leveraging clinical expertise, with leading raw material technology and in-house manufacturing capabilities Forté Healthcare ensures optimal outcomes for pressure injury prevention, infection control and patient comfort.

You’re Covered by Forté Healthcare’s ‘Successful Solution Guarantee’

At Forté Healthcare, we are so confident in the care and performance our support surfaces deliver, that we back our products and expertise with our ‘Successful Solution Guarantee’.

Here’s how it works:

Our team of specialists will help you navigate our product range to correctly match our support surfaces with your care environment and patient risk profile. This ensures you achieve the highest levels of patient care and pressure injury prevention.

If, for whatever reason the product we recommend isn’t helping you achieve the outcome you expected, we’ll work with you until it is. And in the unlikely event we still cannot provide the right solution.

We’ll refund you 100% of the charges to date.