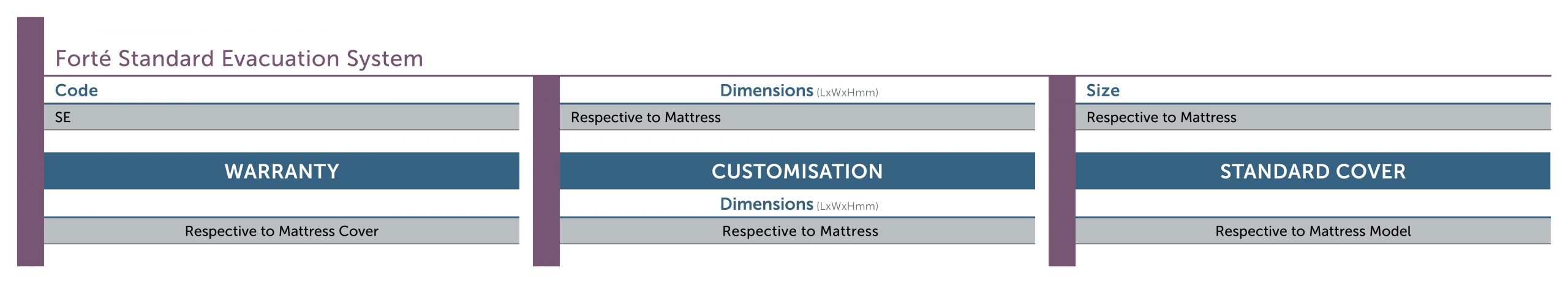

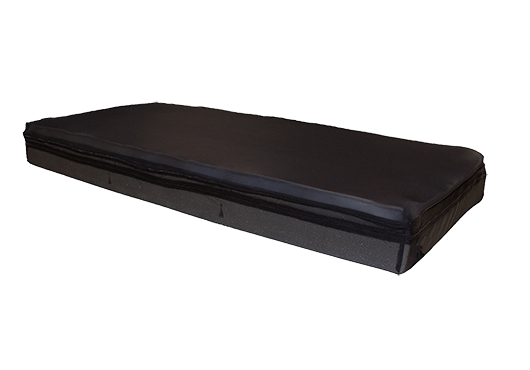

Forté Standard Evacuation System

Forté Standard Evacuation System

The Forté Standard Evacuation System can be customised into most of the Forté Mattresses. With all seams High Frequency Sealed and Welded, the Forté Standard Evacuation System does not compromise on hygiene and infection control. Staff safety and risk of injury is mitigated as the Forté Standard Evacuation System significantly reduces force required to evacuate a patient across a range of floor surfaces.

Must be purchased in conjunction with a full mattress cover

Features

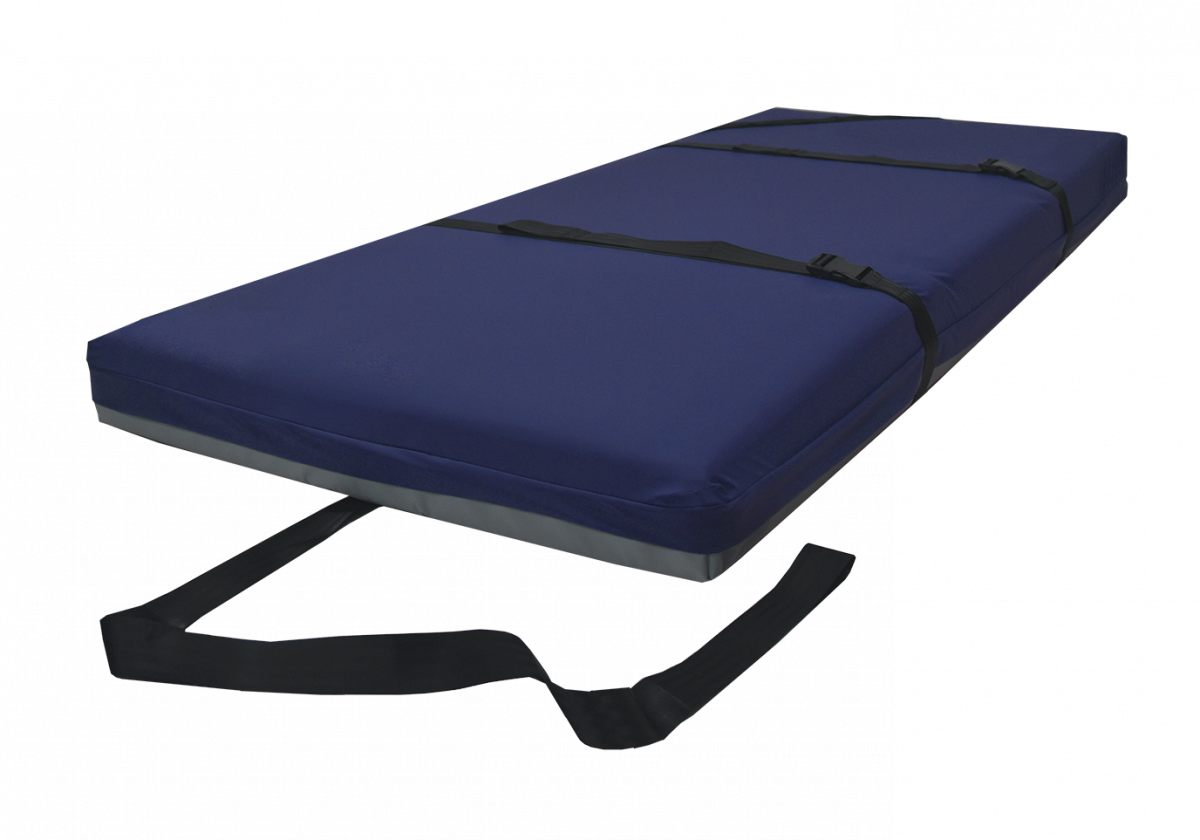

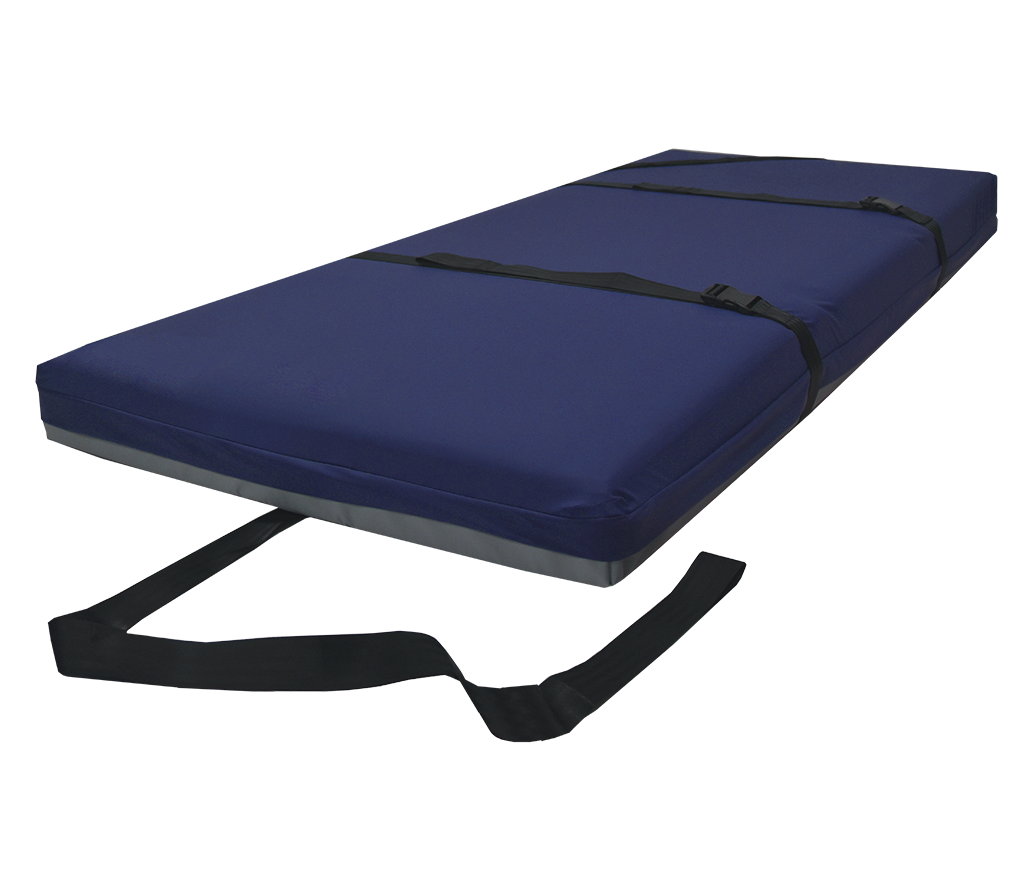

EVACUATION STRAPS STORE IN POCKETS UNDERNEATH THE MATTRESS

- Prevents straps from becoming entangled with bed base and/or other equipment

- Straps are kept clean and free of infection

- Wipe Clean pocket with high frequency welded zipper for infection control

- Being integrated within the mattress ensures the evacuation system cannot get misplaced. Staff can be rest-assured that the evacuation system is always ready for use.

CROSS-PATIENT STRAPS

- High strength straps ensure stability and protection

- Large clips allow for quick attachment and tightening

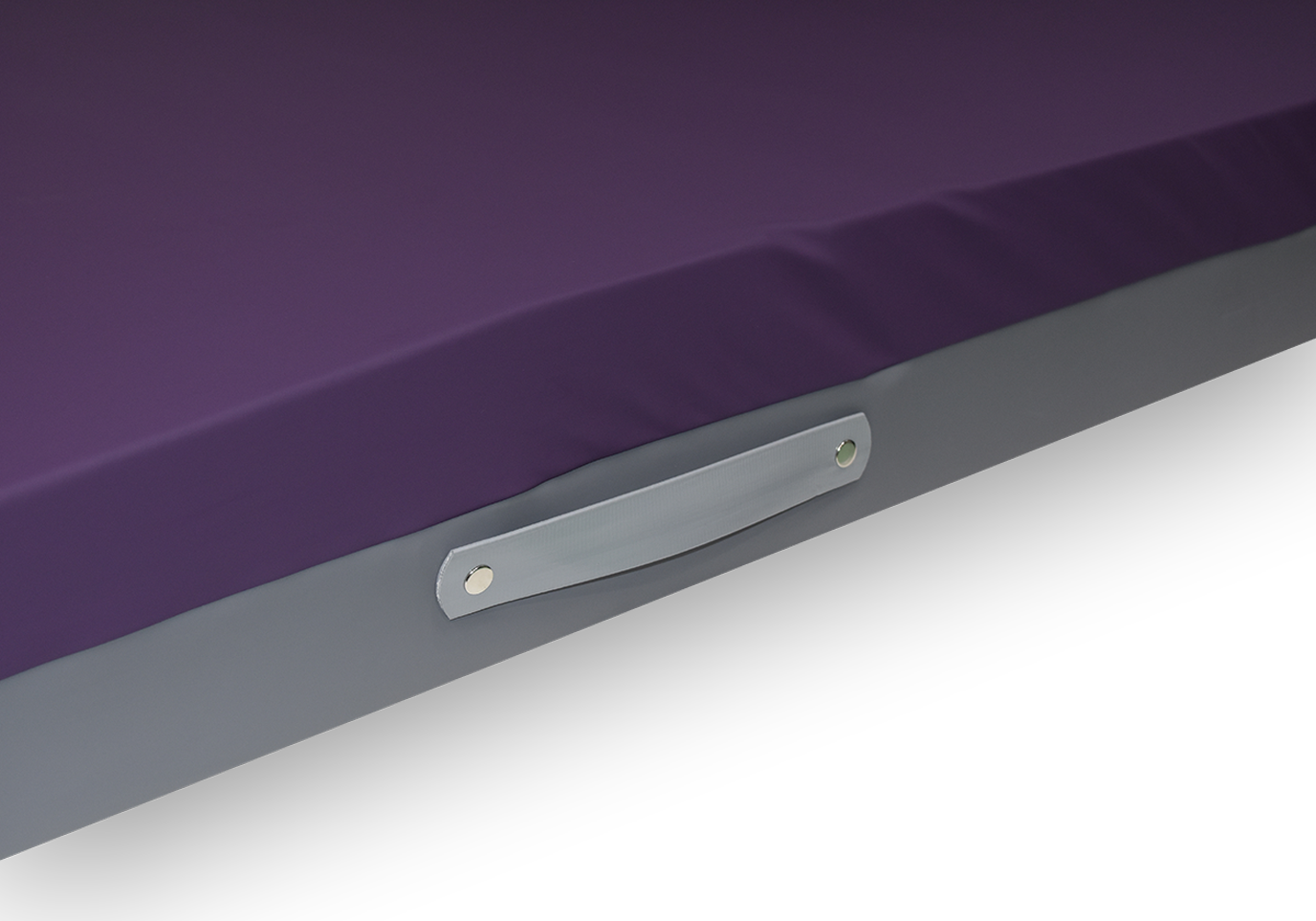

HIGH FREQUENCY SEALED AND WELDED SEAMS

- All external seams High Frequency Sealed, Welded and fused for added infection control

- Prevents ingress of fluid through seams

DUAL EVACUATION PULL-POINT

- Option of pulling from head or foot end

Common Customisations

About the Standard Evac

Mattress Evacuation System

High Durability

Customisable

Hygienic

Safety

STAFF AND PATIENT SAFETY

In any healthcare environment, staff and patient safety is a pivotal concern. Evacuation systems need to be used to ensure patients who are unable to walk can be safely evacuated in an emergency.

The Standard Evacuation system is integrated within the mattress cover which means the evac system cannot get misplaced.

IMPORTANCE OF INFECTION CONTROL

Effective infection prevention and control are central to providing high quality healthcare for patients and a safe working environment for those who work in healthcare settings. The Australian Guidelines for the Prevention and Control of Infection in Healthcare (the guidelines) provide evidence-based recommendations that outline the critical aspects of infection prevention and control, focusing on core principles and priority areas for action.

The guidelines describe the best way to prevent and reduce infections occurring in healthcare settings including resistant infections. The guidelines include how to manage common infectious agents, for example, gastrointestinal viruses and evolving infectious agents, for example, influenza or multi-drug resistant organisms.

Any infectious agents introduced into the body can establish infection. In all healthcare settings, reusable medical devices, such as mattresses, should be handled in a manner that will prevent patients, healthcare workers and environmental contact with potentially infectious material. Post COVID-19 pandemic, Cleaning and infection control have become a bigger concern than ever before.

Appropriate reprocessing or precautions must be implemented for reusable equipment, such as the mattress to prevent patient-to-patient transmission of infectious agents.

Principles of reprocessing reusable medical devices include:

- Only Therapeutic Goods Administration (TGA)-included reusable medical devices should be used; before purchase, healthcare facilities should ensure that manufacturer’s reprocessing instructions are provided and are able to be followed by the healthcare facility.

- All reusable medical devices and patient-care equipment used in the clinical environment must be reprocessed according to their intended use and manufacturer’s advice.

However, Other standard precautions must take place. Standard precautions are basic infection prevention and control strategies that apply to everyone, regardless of their perceived or confirmed infectious status. Strategies include hand hygiene, personal protective equipment, cleaning, and appropriate handling and disposal of sharps. These are the first-line approach to infection prevention and control in health service organisations and are routinely applied as an essential strategy for minimising the spread of infections. Standard precautions minimise the risk of transmission of infectious agents from one person or place to another, even in high-risk situations, and render and maintain objects and areas as free as possible from infectious agents

Specifically, in relation to the support surface, there should be no exposed materials that will absorb fluid. As such, every mattress cover and/or mattress accessory in the facility environment must have high frequency welded seams (as opposed to sewn) to meet infection control requirements and prevent seepage of fluid through open sewn seams. These electromagnetically fused seams protect against the risk of penetration fluid as they 100% seal off to prevent ingress of fluid or infection. To ensure extra strength, Forté reinforces welded seams with additional heavy duty stitching at stress points within the cover.

In addition, Forté mattress covers and foam cores are treated with anti-microbial treatment to prevent the growth of mould and bacteria on soft surfaces. It is a recommendation that soft surfaces must be impregnated with antimicrobial (self-disinfecting) materials.

All Forté products are included and registered onto the Australian Register of Therapeutic Goods (ARTG). Unless exempt, reusable medical devices must be ‘included’ onto the ARTG before they may be supplied in Australia.

Forté mattresses can withstand stringent infection control procedures and have been designed to suit facility standards so you can have peace of mind that all areas of your facility are a safe, clean environments for staff and patients.

MADE IN AUSTRALIA

The Forté production facility in Armidale is specifically dedicated to Medical Mattress’ design, development, and production. This ensures unrivalled expertise and process control for superior quality, value, and performance. Forté utilizes leading global technology and research in the design and development of each medical device. Products manufactured by Forté in Australia are produced in compliance with local regulatory standards and exceed clinical standards recommendations such as European Pressure Ulcer Advisory Panel, National Pressure Injury Advisory Panel and Pan Pacific Pressure Injury Alliance – a quality you can trust!

Australian made by Forté Healthcare in Armidale NSW, Forté products are synonymous with quality, performance, longevity, and functionality and is trusted by leading Hospitals and healthcare professionals to deliver clinical results and positive outcomes.

Why is it important to purchase Australian made products?

By purchasing products from Forté you are investing into the future of pressure injury prevention in Australia, creating regional jobs and boosting our economy for the better of everyone. Australian Made for Australian Care.

WHAT IS FIRE RETARDANT?

What does Fire Retardant mean? A fire retardant is a substance that is used to slow down or stop the spread of fire or reduce its intensity. This is commonly accomplished by chemical reactions that reduce the flammability of fuels or delay their combustion.

All Forté covers meet BS5852 Source 5 Specification. Covers meet BS 6807 ignition source 5 and BS 7175 ignition source 5 standards.

What is BS5852 Source 5 Specification?

Test methods for assessing the ignitability of covers and fillings used in upholstered products such as mattresses, by smouldering and flaming ignition sources

BS5852 is a British Standard that describes methods for assessing the ignitability of single material combinations, e.g. cover and foam core of a mattress, when subjected either to a smouldering cigarette or to flaming ignition sources of thermal output ranging from that of a burning match to that approximating to the burning of four double sheets of full-size newspaper, as might be applied accidentally to any item of furniture.

Source five is one out of seven ignition sources of the BS5852;

| Source | Combustion type | Ignition source | Details | Energy inputs, Kw.h |

| 5 | Flaming | Crib | 17 g | 0.08 |

What is BS 7175 ignition source 5 Specification?

Methods of test for the ignitability of bedcovers and pillows by smouldering and flaming ignition sources. BS 7175 describes methods of test for the ignitability of bedcovers and pillows when subjected to smouldering and flaming types of ignition sources of differing severities.

Source five uses a wood crib 5. A crib is composed of wooden planks glued together. Lint is attached to the bottom. After adding propane-diol, the crib is placed on the test rig and ignited with a match. If no flaming or progressive smouldering is observed on both cover and foam core, the test is recorded as no ignition and the material passes the test.

Any evacuation system should be fire retardant.

Manufacturing

Leveraging clinical expertise, with leading raw material technology and in-house manufacturing capabilities Forté Healthcare ensures optimal outcomes for pressure injury prevention, infection control and patient comfort.

Hear what Health Professionals say About Forté Healthcare Mattresses…

You’re Covered by Forté Healthcare’s ‘Successful Solution Guarantee’

At Forté Healthcare, we are so confident in the care and performance our support surfaces deliver, that we back our products and expertise with our ‘Successful Solution Guarantee’.

Here’s how it works:

Our team of specialists will help you navigate our product range to correctly match our support surfaces with your care environment and patient risk profile. This ensures you achieve the highest levels of patient care and pressure injury prevention.

If, for whatever reason the product we recommend isn’t helping you achieve the outcome you expected, we’ll work with you until it is. And in the unlikely event we still cannot provide the right solution.

We’ll refund you 100% of the charges to date.